The 2019 BLMRA 12 hour lawnmower race

Fri 9 August 2019Tagged: lawnmower, metalwork

We raced at the BLMRA 12 hour again this year.

Preparation

Last year's 12 hour went well, with delays caused only by the bent clutch and flat tyres. Additionally the mower didn't handle as well in slow wet conditions as it did in hard dry conditions. So with that in mind, for this year I built a new clutch out of a more substantial piece of steel:

And replaced the old lawnmower wheels with the fancy wheels that everyone else uses that have little bolts around the rim to keep the tyre from falling off:

And improved the steering geometry by separating the inner track rod ends:

I have a video of a 3d-printed prototype from before I committed the design to steel.

Previously both inner rod-ends were mounted in the same place. This meant that as the steering shaft rotates, both track rods move left/right by the same distance. By separating the ends, the rod end which is at the "bottom" moves primarily in the horizontal axis, while the rod end that is at the "side" moves more in the vertical axis, which reduces its horizontal movement, which means the inside wheel is pulled by more distance than the outside wheel is pushed, getting us closer to true Ackermann geometry.

We also added an electronic rev limiter and made a handful of other small improvements.

The new wheels use smaller hubs, which have smaller bearings than we were using before. After our test weekend the front wheel bearings were feeling slightly gritty so I picked up a new pair of hubs from R&M Racing on the Saturday morning of the race, and fitted them, so that we'd have fresh bearings to race with.

The race

James and I drove the mower again, but Feroz couldn't drive because of eye trouble, so we had Ruari driving this year. Matt Game came to help in the pits again, and Rory Lucas also came to help in the pits, along with Emma and Catherine (James's wife) taking care of hospitality and timing.

We passed scrutineering on the first try, which was good. I wasn't sure whether our front axle was now too wide, or if they would take issue with the presence of the rev limiter. But they measured the distance between the front wheels and were happy with it, and they didn't notice the rev limiter.

James and Ruari did their practice sessions with no incident, but when I set off for mine the belt started making an awful noise, and when I lifted off the throttle at the first corner, it jumped off the front pulley and got a bit shredded. That's annoying. I thought we'd solved all the belt problems by now. The circuit this year was on a field that was not quite level, so there were 2 men in a "Gator" towing mowers back up the hill. I got a tow back to our pit garage and we put a new belt on.

We qualified 33rd, but I only got about 5 laps of qualifying. I'm not sure which one of us set the best time in qualifying, but I think I at least would have been able to do faster laps if I had got some practice in beforehand.

James got a good start, and his first stint went OK for the most part.

At one point someone hit him from behind and one of the mudflaps got stuck under the wheel arch. James didn't know what had happened and was concerned about the noise it was making, so he made a pit stop. We briefly tried to pull the mudflap out but it was too stuck so we just left it and he carried on. Subsequently he broke down and got towed back. But we couldn't find anything wrong with the mower, and it started up OK by the time it got back to the pit, so we refuelled and Ruari set off for his first stint, which, apart from a brief pause to throw off his steamed-up goggles, was completed without issue. At this point we speculated that James might have ran out of fuel, as the breakdown was near the end of the hour, although we know that a tank of fuel normally lasts just over an hour.

After Ruari finished his hour, I went out for my first stint. This mostly went without issue, and I was enjoying it very much. The mower handled really well, and it was much more pleasant to drive on long straights with the rev limiter, rather than having to lift off the throttle. About 51 minutes in the engine started sputtering and backfiring, which is a sign that it is running on fumes and about to run out of fuel, so I pitted and we refuelled it, then I carried on to finish the hour. At this point we were pretty confident that James had stopped due to running out of fuel, so we altered the pit strategy to include a quick refuel stop halfway through each stint. The track this year was much faster than previous years, so we were obviously using fuel faster. Also, whenever we're hitting the rev limiter instead of lifting off the throttle, we're chucking a load of unburnt fuel out the exhaust that we previously wouldn't have been.

James and Ruari's second stints were both pleasantly uneventful, but on my second stint the belt jumped off the front pulley again. This is extremely annoying. The belt wasn't visibly damaged this time so we just refitted it and carried on. It jumped off again in James's third stint, and again we refitted it and carried on.

Ruari had gone to sleep after his second stint, and had set his alarm incorrectly, so at 2.50am, 10 minutes before he was due on for his third stint, he was quickly awakened from a deep sleep. It was quite cold at this point of the morning, and waking up quickly from a deep sleep didn't help. I've never seen anyone shivering as much as Ruari was then. We tried to give him a can of energy drink, but he couldn't hold it still enough to avoid shaking the contents out the top. James's stint ended with the belt jumping off again, which gave Ruari a few more minutes to wake up while we refitted it again.

At the start of my third stint, I merged onto the track in amongst traffic. I wasn't yet in "race mode", having been sitting in the pits only 15 seconds prior, and quite badly missed my braking marker for the first corner. When I realised my mistake I braked hard, and miraculously managed to avoid hitting any of the other mowers, but my mower swung around a bit and slammed into a large hay bale. The mower was thrown up in the air a bit and ended up facing the wrong way, but I was still on it and it wasn't obviously damaged, so I turned round and carried on. Over the course of this stint the bonnet became increasingly wobbly, and eventually it was getting too bad so I had to pit so that we could repair it.

It got cracked in the crash, and the crack was spreading as it was wobbling around. We repaired it by drilling holes either side of the cracks and tying them together with cable ties.

After this I carried on some more and the belt jumped off again. We decided to fit a new belt at this point to see if that would cure anything, which ended up costing 18 minutes, but did solve the issue for the rest of the race. Right at the end of the stint the front left wheel became wobbly, so I pitted and we found that one of the wheel bearings had collapsed. Good job we had a spare pair of hubs! Part of the collapsed bearing was stuck to the spindle, so this was removed with the angle grinder, but changing the hub only took a couple of minutes.

James's final stint was completed without issue. In Ruari's final stint somebody else had a big accident which resulted in "full-course yellows" for a few laps. This means there are flashing yellow lights and no overtaking is allowed. All of the mowers bunch up together. When the full-course yellows were over, Ruari was in amongst a bunch of faster mowers, and ended up setting his fastest lap. About 10 minutes before the end of his stint, he pitted because one of the rear tyres was low on air. We put a new one on and then I went out for my final stint.

I realised quite quickly that the rev limiter was no longer working, but I wasn't sure why. After a few laps the mower sputtered to a halt. I managed to pull off the track and noticed that fuel was gushing out of the bottom of the fuel tank. That was quite concerning. I got off and held my finger over the bottom of the tank to stop the flow of fuel and awaited assistance from the pit crew. I also noticed at this point that the fuel tank was very loose, and the live wire that powers the rev limiter was broken in half. We later concluded that the fuel tank had got knocked off its mounts during the crash at the start of my third stint, and had been slowing working its way free. It was then able to wear through the wire for the rev limiter, and eventually knocked the fuel hose off. Having a loose live wire flapping around next to a fuel leak is the closest we've ever come to a fire, but thankfully it didn't result in one.

Emma ran to the pit to fetch the tools to take the bonnet off, and then we reconnected the fuel hose and pushed the mower back. We removed the loose live wire, secured the fuel tank with more cable ties, and continued racing.

With about 20 minutes left to go, the front right wheel bearing wore out, the same way the left had earlier on. I cut across the track and drove straight to our pit where we quickly changed the hub and carried on. In hindsight I should probably have attempted to complete the lap I was on, because I ended up cutting out more than half of the lap. I was just concerned that the wheel would fall off entirely if I kept driving.

After that the belt started slipping a bit. I was concerned that it was damaged and was going to break, which would have been fatal as at this point we would not be able to put a new belt on in time to finish the race. So I drove quite gingerly, making sure not to put too much strain on the belt, and eventually crossed the checkered flag!

We finished 26th overall, of 50 entries. We were also given the "best pit" award, although we don't know why, and we didn't actually receive it as we were sleeping during the prizegiving. Current theory is that it was a joke because our pit was full of drinks and snacks instead of tools and spares.

We wasted about 90 minutes in total on unexpected repairs to the mower, in which time we would have been able to do 40-45 extra laps, which would have gained us 7 places.

For next time

People want me to build a new mower from scratch, but I don't think I'm going to. I'm currently planning to strip the current mower down to the chassis, and then build it up as if I was building a new one from scratch. I don't think the Countax chassis is actually that bad. There's certainly scope to do a better job of it than I have done so far.

We need to get to the bottom of the belt falling off. When it comes off, it always comes off the top of the front pulley, never the rear, even though the front pulley has some rollers next to it to keep the belt from coming off and the rear pulley has nothing. It also seems to happen more as the belt gets worn out, possibly because the belt gets more flexible. After the race I measured the rear pulley and found that it is out of level by about 1°, pointing up at the front. When you lift off the throttle (and the "tight" run of the belt from the front to the rear turns into a "slack" run) the rear pulley is pushing the belt forwards with quite a lot of power. If it's pushing hard enough, then that might be enough to force the belt up and past the rollers by the time it gets to the front pulley. Some of the other mowers don't have anything at all to keep the belt on the front pulley, and they don't seem to have it fall off as often as we do, so I'll definitely make sure to fit the rear pulley square to the chassis.

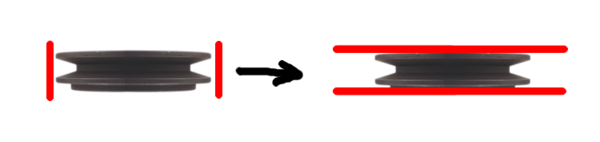

Additionally, Matt had a great idea for a better way to keep the belt on. Instead of having rollers on the chassis, next to the pulley, we should instead just make the pulley larger by fitting big metal plates at the top and bottom:

The metal plates are fixed to the pulley, and spin around with it, so that even if the belt gets slack and lifts away from the pulley, it still can't move up or down, so it'll just re-engage with the pulley as soon as it becomes tight again. The bottom plate might need to be removable so that we are able to fit the belt, but the top one at least can be permanently welded to the pulley.

I was very disappointed with the bearings in the new front hubs. R&M Racing inform me that they're working on a new hub design that takes larger bearings. If that comes to fruition then I'll probably just buy them, or alternatively I might try to machine some new hubs of my own. It's not a very complicated part, it could just be a big chunk of aluminium with a hole up the middle for the bearings to sit in, and 3 concentric threaded holes on one face for the rims to bolt on to. The only tricky bit is making sure the 3 holes are actually concentric. Ideally you'd use a milling machine, but I think a template and a pillar drill would suffice.

The new wheels did a great job of keeping the bead from breaking when the tyres got low on pressure, although the tyres got low on pressure faster than they should. I'm not entirely sure where they're leaking, but I'd like to stop them leaking for next year. Possibly they just want refitting using bead sealant around the bead and on the bead-retention bolts.

We should fit some sort of battery isolator so that next time there is an exposed live wire, we can just immediately disconnect the battery and rule out any unwanted sparks.

The centre of gravity wants lowering, as does the seat.

And also it wants a better bracket for the fuel tank, so that it can't fall off even if you have a big crash.

If you like my blog, please consider subscribing to the RSS feed or the mailing list: