More inlet pressure measurements

Tue 18 April 2023Tagged: wigwag, science

I'm not completely sure what has changed, but I'm now getting more convincing-looking inlet pressure data.

This came about because I tried to reproduce the real-life observations in the simulator and did not succeed, so I repeated the real-life measurement and this time I got a different result. (As any good scientist knows: if you don't get the results you want, you should repeat the experiment until you do).

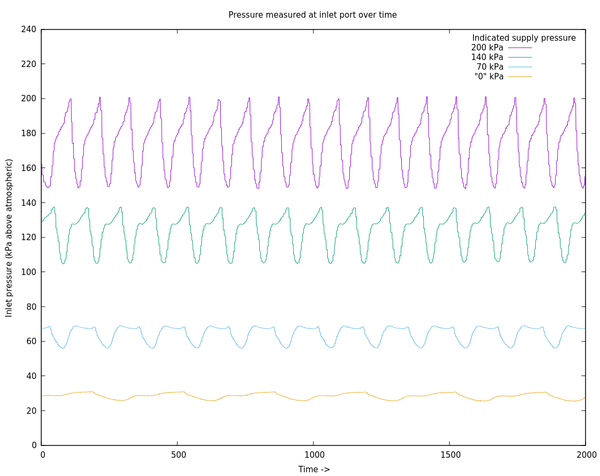

This chart shows today's measurement of inlet pressure over time, for representative samples with 4 different supply pressures:

The "0" kPa line is from running with a 0 indicated on the regulator pressure gauge (video), which maybe is about 30 kPa judging by the line on the graph?

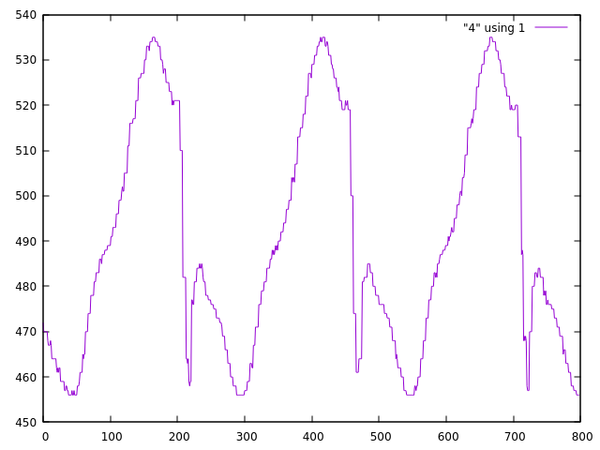

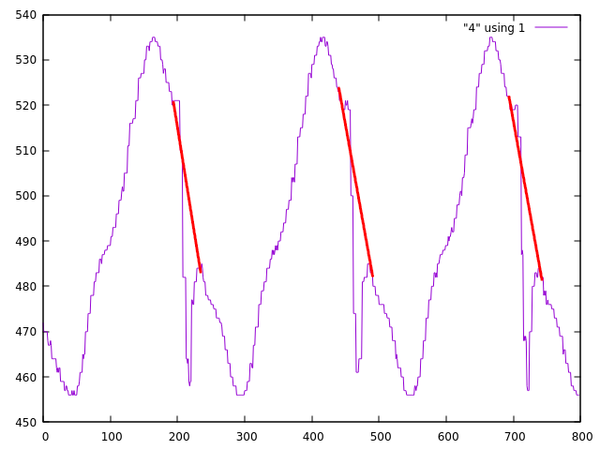

And the trace from before was more like this:

That's with 200 kPa supply pressure. If we draw straight lines past the sharp dips, it looks more like the new version:

So my best guess at what has happened is that the engine previously had a leak from the port faces at some point during the cycle, which is now fixed. Such a leak would allow air to rapidly vent to the atmosphere through the inlet port, instead of having to pass through the cylinder.

In between, I had dismantled the engine, cleaned all the dirty oil off, re-lubricated and reassembled. I don't know that that would have made a substantial difference, but I can't think what else I changed.

The other obvious difference is that the peak pressure now approximately matches the indicated supply pressure instead of exceeding it. I also don't know why this would have changed, but it could just be that the gauge on the compressor is not very accurate.

Simulator

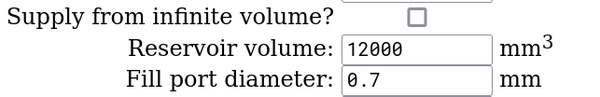

I added an option to the simulator to allow the configuration of a "reservoir" which supplies the cylinder, to allow the pressure to drop when the port opens and then slowly fill back up once it closes. You can use it if you turn off the "Supply from infinite volume?" option.

It basically acts like a spherical air tank of a given volume, with an orifice connected to the inlet port on one side and an orifice connected to an infinite volume of the nominal supply pressure on the other side.

The reservoir configuration of a 12000 mm3 volume and a 0.7mm fill port gives pressure drops roughly matching what I observed in real life.

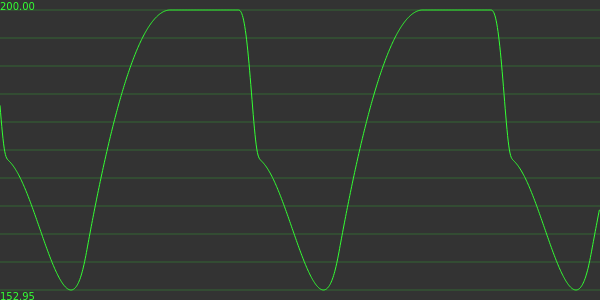

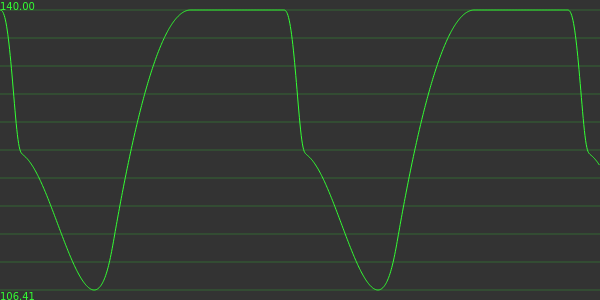

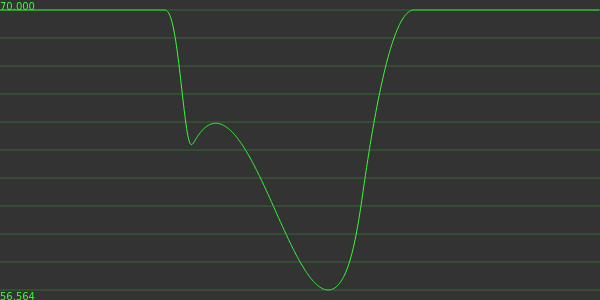

I don't yet have a convenient way to overlay the plots on the same chart, but here are traces of the reservoir pressure from the simulator for 200 kPa, 140 kPa, and 70 kPa supply pressures, with the load manually adjusted as per the calibrated losses so that it runs at the same speed as the real-life engine did at the same pressure.

The range between the maximum and minimum value is shown in the number at the left hand side. Comparing this to the real-life chart from above (shown again for your convenience):

We can see that the magnitude of the pressure drop is about the same in all cases, although the waveform is not quite the same.

With 200 kPa supply, the pressure drops to about 150 kPa. With 140 kPa supply it drops to about 105 kPa, and with 70 kPa supply it drops to about 55 kPa.

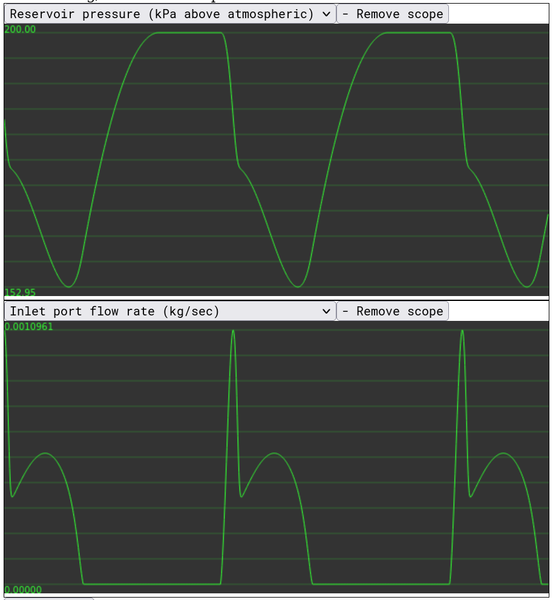

The shape of the falling edge of the reservoir pressure plot kind of mirrors the inlet port flow rate (as you'd expect):

I don't know why we don't see a shape like this in real life.

Possible explanations for the differing waveform include that the hose in real life is not actually a spherical reservoir, or that the regulator is actually supplying the hose with high pressure air through a variable-sized orifice, whereas the simulator has a fixed-size orifice supplying lower pressure.

But I'm happy that the magnitude of the pressure drop lines up with real life.

Next

I'll probably want to re-record the loss calibration data now that the engine is running better (the fact that it can now run on lower pressure suggests that losses are reduced), and re-calculate the calibration curve in the simulator now that I can use the "reservoir" model to simulate the pressure drop in the supply hose.

I also still want to try adding a small reservoir to the real-life engine, to see if it reduces the magnitude of the real-life pressure drop.

If you like my blog, please consider subscribing to the RSS feed or the mailing list: