Five interesting things from the Science Museum

Wed 23 August 2023Tagged: science

I enjoyed a quick visit to the Science Museum at the weekend, and here are a few of the interesting things I saw.

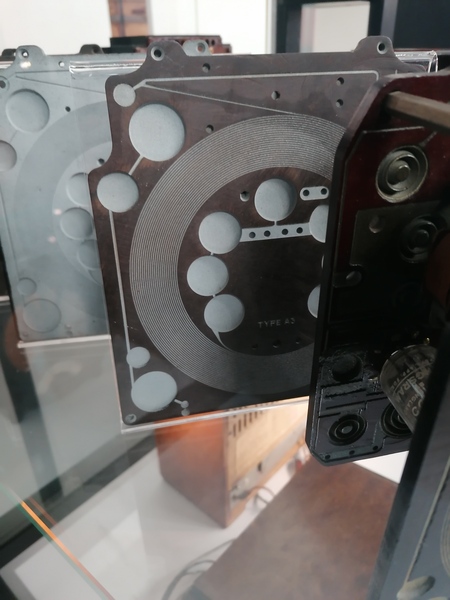

Primitive circuit boards

This is obviously an exhibit showing some primitive circuit boards at various stages of manufacture, but I think the exhibit is being updated because there was no obvious explanation posted.

It looks like there is a wooden pattern (out of shot to the left), which is then cast as a metal part, which then gets machined and painted, and then turns into a working circuit board. Eh? Won't everything short out through the middle?

It turns out that's not how it works at all. There is an explanation on the Science Museum website, it's a Passive component plate, type A3, for Sargrove sprayed-circuit radio receiver.

The "wooden pattern" is actually Bakelite, and is not a pattern at all but is the insulating substrate for the circuit. This is then sprayed (how?) with metal and graphite, and then the top is machined down to remove all of the metal except in the grooves!

It's kind of the opposite of a modern circuit board, where the conductive part is raised up off the substrate. In these Sargrove circuits, the conductive part is sunk down.

Apparently "his idea was never taken up generally, partly because it was seen as a threat to jobs", which sounds ridiculous now given how many modern jobs are dependent on our ability to produce cheap circuit boards.

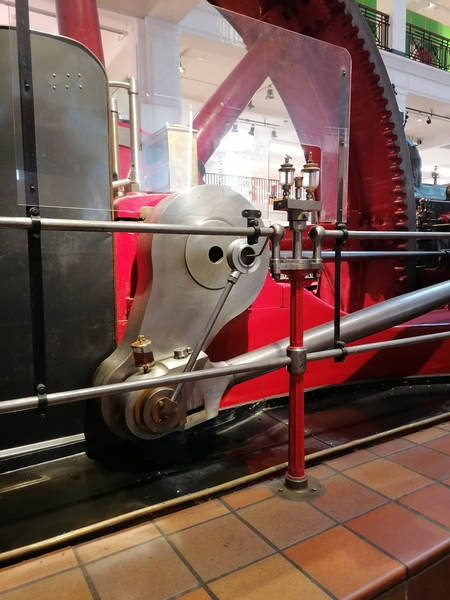

James Watt steam engine indicator

This is a device for plotting pressure-volume diagrams from steam engines. I have done this for my Wig-Wag engine by attaching electronic sensors, but this device works purely mechanically.

The central body is a spring-loaded pneumatic cylinder, which gets plumbed into the steam engine's cylinder pressure. There is a pencil mounted horizontally at the top of the "plunger", so as the pressure in the engine rises, the pencil rises.

The piece of card is attached to a piece of string, which is biased to the right by the weight, and the hook on the left end of the piece of string is presumably attached to something on the engine which moves in proportion to the stroke.

Now as the engine completes a cycle, the card moves left and right, and the pencil moves up and down, and plots a representation of how the pressure in the engine changes throughout the cycle. Ingenious.

As a bonus, just at the edge of the shot you can see the Watt micrometer. There is an interesting Machine Thinking video on this device.

Electric governor

It was quite hard to take a photograph of this, but maybe you can see what I'm getting at.

This is a steam-turbine-powered electricity generator. The output voltage is applied across a solenoid which pulls a metal rod (right of pic, vertical), and the rod is connected to a long lever which actuates a steam "throttle" (left of pic), to create a feedback loop which keeps the output voltage constant.

This is a nice alternative to the centrifugal governor, and it directly controls the output voltage, which is what you care about, rather than the engine speed.

Rotating oiler

Two oil cups are mounted on the railing around the outside of the engine, with a brass pipe poking into an "eye". The eye is on the end of a long hollow arm attached to the crank pin. Oil that drips into the eye can run down the inside of the arm, into some (presumed) oil ways in the crank pin, and lubricate the crank bearing. The arm keeps the eye on the centre line of the crankshaft even though the crank pin moves around in a circle.

It looks like this is actually not used, because both of the oil cups on the railing are empty, and there is a third oil cup installed directly on the con rod, but it's a nice idea anyway. I guess it is prone to leaking because the arm spends 50% of its time upside down.

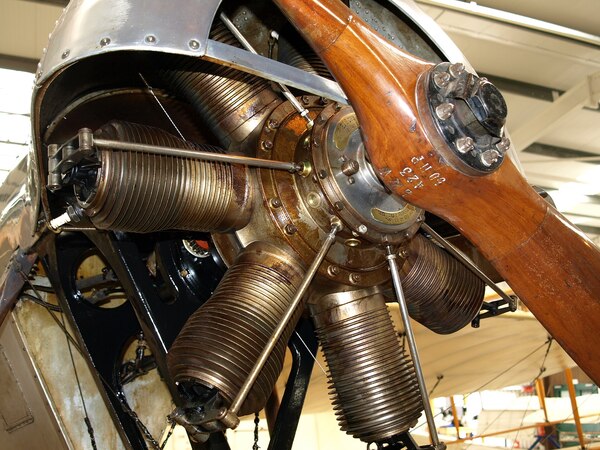

Gnome rotary engine

There is an area in the "Flight" section on the top floor full of aircraft engines. This area is sadly very poorly lit which makes it hard to see much more than "metal parts are here" unless you look closely. I think it's more meant to provide an aesthetic than be an actual exhibit.

But the Gnome engine is worth an exhibit in its own right. The example at the Science Museum is cut away so you can see what's inside.

I didn't think to take any pictures, but here are some I found online:

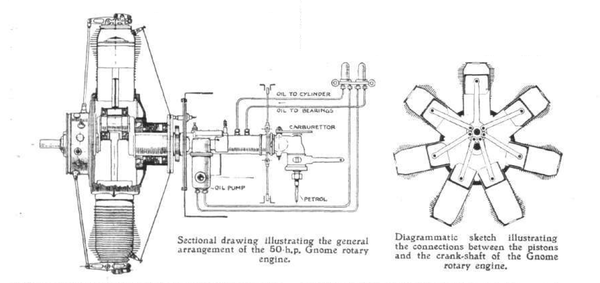

Instead of mounting the crank cases to the fuselage, and the propellor to the crankshaft, this engine works the other way around. The crankshaft is fixed to the fuselage, and the propellor is attached to the crank cases. When the engine is running the entire thing spins around with the propellor! Supposedly this helps with cooling.

But it's not quite as simple as that. If you turned around an ordinary engine so that the fuselage and the propellor were swapped, you would have issues connecting the throttle cable and fuel. The Gnome engine supplies fuel/air mixture through the inside of the crankshaft. The exhaust valves are on the top of the cylinders and are operated with push rods. The inlet valve is in the top of the piston and is spring-loaded with no actuator. The valve simply opens when the pressure in the cylinder is lower than the pressure in the crank case, and shuts when it's the other way around. Ingenious!

The Gnome engine is French and is known as a "monosoupape" (single valve) because there is only one obvious valve per cylinder.

I have a vague idea for a model steam engine that works a bit like this. Each cylinder would have a single port through which the steam both enters and exits, like in an oscillator. Except instead of oscillating back and forth between an inlet port and an exhaust port, the cylinders would be continuously rotating, fixed to the flywheel (perhaps even bored directly into the flywheel), and the port would be exposed to steam pressure for ~half the cycle and vented to atmosphere for the other half.

I think one difficulty would be in sealing the port face. Oscillating engines can get away with just using a spring because the rotation is minimal. The "rotary" version could maybe use a spring but would need a thrust bearing to allow the spring to rotate.

If you like my blog, please consider subscribing to the RSS feed or the mailing list: