My Wig-Wag

Sat 8 April 2023Tagged: wigwag, metalwork

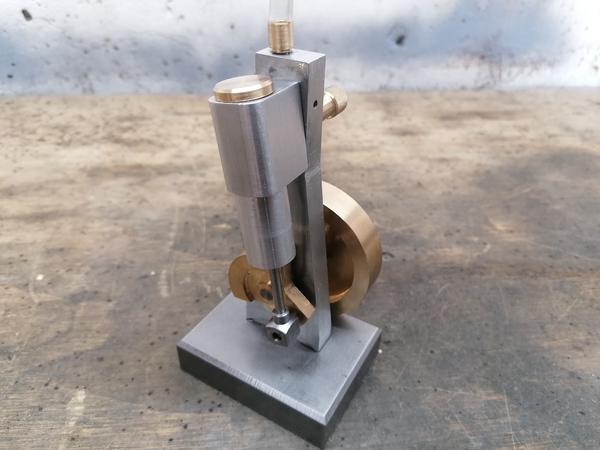

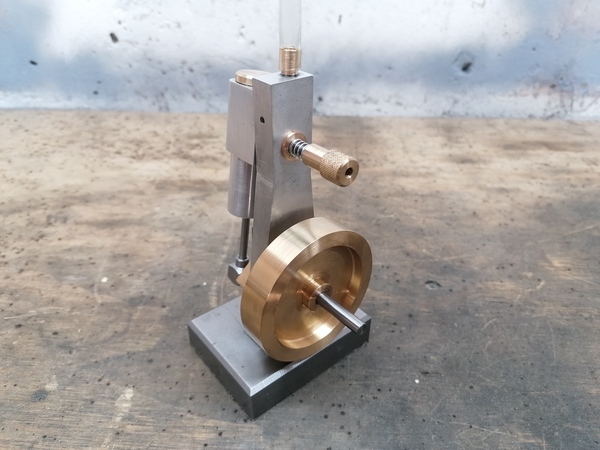

I have finished building the Wig-Wag engine that I mentioned in my post about the simulator, and it runs! Great success.

I made it with my mini lathe and CNC mini mill.

I'm running it on compressed air rather than steam, purely for convenience. I'm more interested in the engine than the steam for the time being (although I am a bit interested in the steam, so maybe I will make a steam boiler one day).

I managed to fit the "pivot rod" to the cylinder out-of-square, which means the port face on the cylinder does not sit flat against the port face on the main column. This is very bad because it means the port faces only make contact in one corner, which leads to premature wear, and because the port face doesn't seal very well, which wastes a load of air and reduces efficiency.

I did try to run the engine with the spring tensioner done up quite tightly to try and make it wear in, but this was a bad idea and I have caused the two faces to gouge each other in the corner where they contact. Bad.

I believe the cause of the problem is that I didn't take enough care when tapping the female thread in the cylinder.

The solution will be to take the pivot rod out and either make the thread a very loose fit and glue it in with Loctite such that it is square, or re-machine the port face on the cylinder so that it is perpendicular to the threaded hole, or a bit of both.

Once I have made the engine run the way it should, the next step is to fit a pressure sensor to the top of the cylinder, and some form of crank position sensor to the crankshaft, and plot pressure-volume diagrams from real life to validate the accuracy of the simulation.

I have a video clip of my engine here:

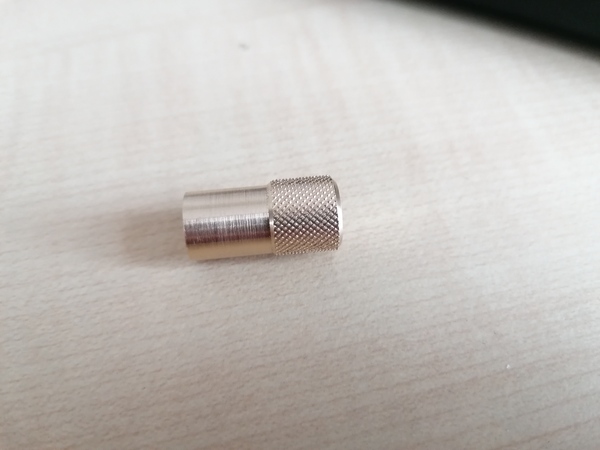

Knurling

The drawings call for the spring tensioner to have a knurled grip on it, but I do not have any knurling tools. My solution was to use my homemade 4th axis to cut a diamond knurl pattern using a 90-degree V-pointed cutting bit, and that worked pretty well:

I have a video clip of that process too. It is not a fast operation.

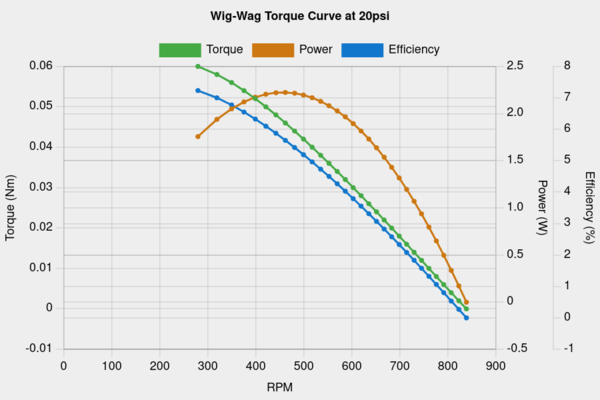

Simulator

There have also been quite a number of improvements to the simulator since last time, most notably it now supports double-acting engines and it can now plot torque curves and pressure-speed curves, for example:

If you like my blog, please consider subscribing to the RSS feed or the mailing list: