Bare minds

Sun 6 October 2024

Back in the Stone Age, humanity was just scraping by with not much more than our bare hands. Working

with AI has showed me that, all this time: we've just been scraping by with our bare minds.

If computers were meant to be bicycles for the mind, then AI is jetpacks for the mind. Read more

I'm building a fixed-gantry CNC machine out of composite kitchen worktop material

Sun 21 April 2024

Composite kitchen worktop material is a good choice for a CNC machine because it is very heavy and very flat.

It is a bad choice because it is quite soft. But mainly it is a very good choice because I already had the material and

it is therefore free. Read more

The watch project

Thu 23 November 2023

My quest at the moment is to try to make a mechanical watch. Specifically I want to make

the movement. I'm not interested in buying a bunch of parts and assembling a watch.

I'm also not interested in cloning a standard movement, I have my own design in mind. Read more

The Douzieme gauge

Mon 2 October 2023

In this post I'm going to explain what a Douzieme gauge is, show you how I made one myself,

and propose some alternative designs for higher precision. Read more

The Egyptian coin box

Sat 5 August 2023

I have invented a new magic trick. It involves a very thin wooden box with 5 locations for coins inside, each

labelled with one of the 5 bodily senses.

A spectator places a coin inside, without telling the magician where it is. The magician

then makes a show of listening to the box, sniffing the box, etc., and successfully determines where the coin was

placed. Read more

How small can you make text with a drag engraver?

Mon 5 September 2022

A drag engraver is a very sharp spring-loaded tool that you can hold in a CNC

spindle and drag over a piece of metal to engrave fine lines. Read more

Toolmaker's Clamp

Tue 14 June 2022

I have managed to make the toolmaker's clamp that I mentioned last time.

It is made out of mild steel, which is soft for a machinist's tool, but harder than wood, plastic, and aluminium, which

are what I'm normally limited to.

Since I made it, it belongs to me, and a clamp is a type of tool, I suppose this is both a toolmaker's clamp

and a clampmaker's tool. Read more

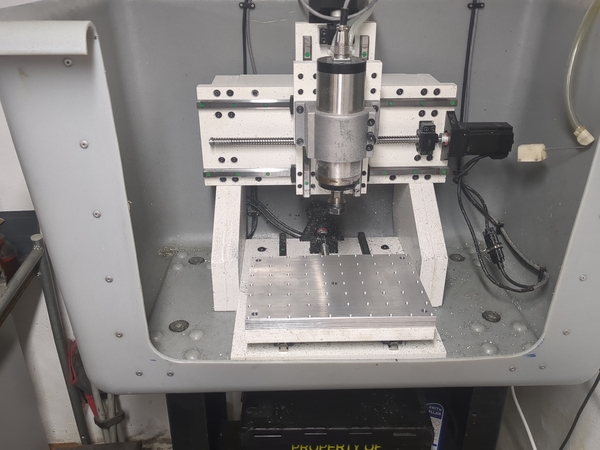

Progress on the CNC mini mill

Thu 9 June 2022

I've made a bit of progress on the CNC mini mill project,

and have made some cuts, although currently it's still not in full working order. Read more

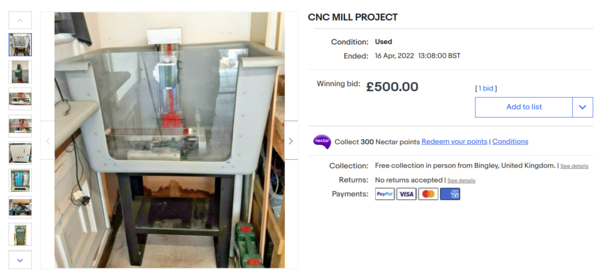

CNC milling machine project

Sat 7 May 2022

I recently picked up an unfinished CNC milling machine project on eBay.

All the mechanical work is done, and almost all of the electronics is

supplied, it's mostly just wiring and software still to do, which for me are the

easiest parts. Read more

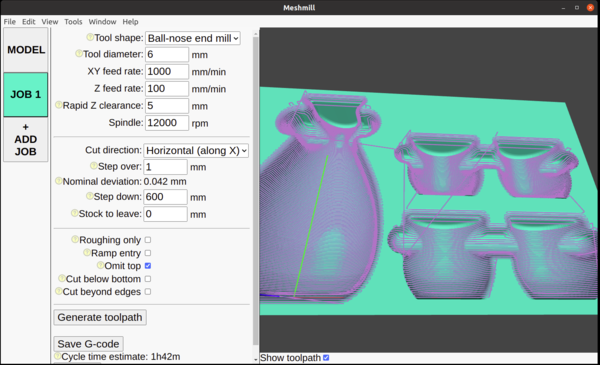

Meshmill: open source 3D CAM

Tue 3 May 2022

For the last couple of weeks I've been working on Meshmill.

It's a new 3D CAM program for Linux. Read more

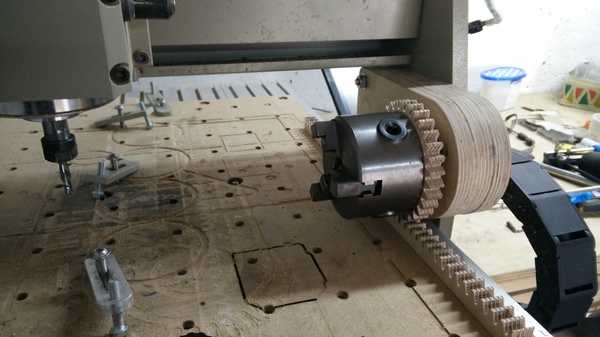

Using the weird rotary axis

Thu 24 March 2022

I've been playing with my weird rotary axis for a couple of weeks now.

It's a rotary axis mounted on the gantry, with the rotation of the chuck geared

off a toothed rack on the table.

I've had a few questions about the practicalities of using it, so this is some of

what I've learnt. Read more

A weird rotary axis for my CNC machine

Thu 10 March 2022

I've built a weird rotary axis for my CNC machine. Rather than a "4th axis" driven by its own motor,

this one is geared off the motion of the gantry. It's still only a 3-axis machine, and there are no electronics changes at all.

As the gantry drives back and forth, a toothed rack on the table causes a matching gear to rotate. The gear holds a chuck,

which holds the work piece, so that when the gantry moves the work piece rotates. Read more

The case for SCAMP

Thu 2 September 2021

All of the SCAMP hardware is now mounted properly inside the case, with no Arduino or breadboard required.

I'm now well into the "long tail" of tasks on this project, where it takes increasingly large amounts of time to

produce increasingly small improvements. Read more

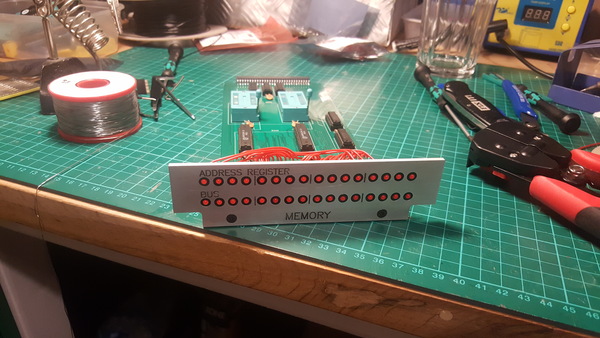

Front panels for SCAMP

Sun 28 February 2021

I've put together the memory card for the SCAMP CPU, including the front panel with LEDs to show

the bus contents and address register. Read more

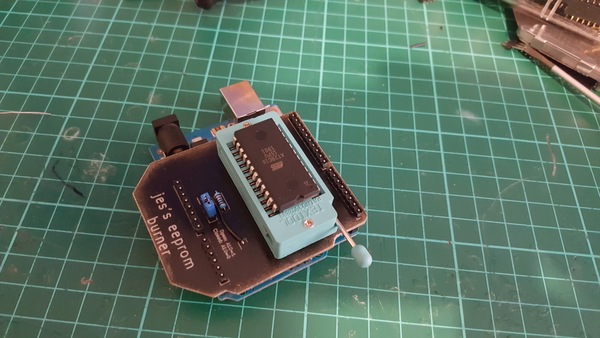

My second attempt at milling a PCB

Mon 15 February 2021

The day after my first attempt at milling a PCB, my new tooling

arrived (a 1 mm drill bit and a 10° engraving tool), so I had another go at making a PCB. Read more

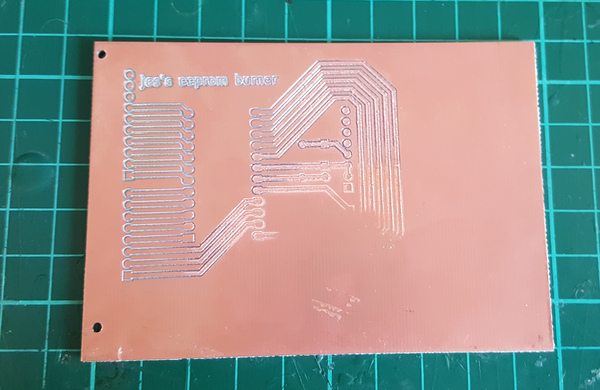

My first attempt at milling a PCB

Fri 12 February 2021

I'm going to get most of the PCBs for SCAMP made by JLCPCB, but I'd like

to try to mill the backplane on the CNC machine because it is both large (expensive at

JLCPCB) and simple (single-sided, no vias, easy to make). Yesterday some small pieces of copper-clad

board arrived and today I had a first attempt to see what would go wrong. Read more

All the gears, no ideas: an escape room puzzle

Fri 18 December 2020

I designed a puzzle for an escape room. The company ended up not wanting to pay for it, but I thought the puzzle was interesting

enough to be worth making for myself anyway. Read more

I made some aluminium keycaps

Sat 28 November 2020

I've made some aluminium keycaps on the CNC machine. I couldn't work out how

to do the CAM in FreeCAD (although I think I have now roughly figured it out), so I instead

wrote a program to render depth maps of STL files so that I could generate toolpaths

with my pngcam program (github). Read more

CNC toolpath generation from heightmaps

Sat 24 October 2020

I've been struggling with generating complex toolpaths in FreeCAD and thought that an easy approach would be to render a heightmap of the

part, and then generating a toolpath from that should be easy.

I understand that this is already a recognised technique, although I could not find an open source tool that

would do it for me. Most of the heightmap-related stuff I found on DuckDuckGo was to do with auto-levelling the bed.

And, anyway, it's a relatively simple idea and a fun challenge, so I did it myself. Read more

First steps into CNC machining

Mon 5 October 2020

I have bought a "6040" CNC router, and have been getting to grips with how to use it.

This journey started with converting the machine to Grbl because I'm not interested in running

proprietary software. Once Grbl was all working correctly, I clamped a small piece of plywood to the bed, fitted a 2mm end mill and made my first cuts, manually

"jogging" the tool position using the buttons in the UGS interface. Read more

How to convert a 6040 CNC machine to Grbl

Wed 30 September 2020

The 6040 CNC machine comes in 2 flavours: parallel port and USB. I don't have a parallel port on the laptop I was

intending to operate it with, so I chose the USB option. This is possibly a "mistake" as the USB option uses

a proprietary USB interface board which is only compatible with Mach3

and therefore only compatible with Windows. But now that I've got it set up with Grbl, I think I prefer this system to

what I would have with a parallel port controlled by LinuxCNC. Read more